ETO

Expertise

Industry leaders navigate you through project management, selection of monitoring equipment, and EPA, NESHAP, OSHA, and other regulatory changes.

Turnkey Systems

Picarro not only builds advanced monitoring systems, we provide complete solutions that include installation, integration, ongoing maintenance, and global support.

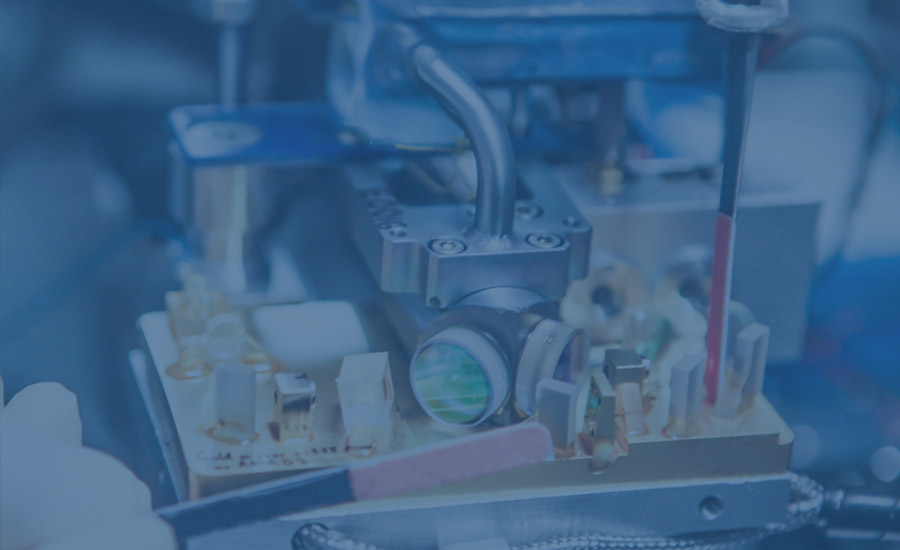

Quality

Ethylene-Oxide-specific measurement technology is integrated into a system built with high-quality materials to ensure superior performance and durability, even in demanding industrial settings.

Advanced Technology

Supported by years of field deployments, Cavity Ring-Down Spectroscopy (CRDS) technology delivers 0.25 ppb lower detection limits of Ethylene Oxide in less than 2 seconds.

Robust Software

Powerful, secure, software platform provides robust analysis and visualization tools, and automates reporting for EPA ERT, CEDRI, audit trails, incidents, and more.

Regulatory Compliance

Knowledge of regulatory requirements such as initial Performance Specification Testing (PST) and development of site-specific QA/QC plans combined with precise, real-time monitoring and automated reporting ensure compliance.