PHMSA Summary

PHMSA, in application to the SAFE PIPES 2020 and the IRA legislations, is proposing 11 amendments to its leak survey and repair (LDAR) requirements. Here is a quick synopsis of these amendments and what it could mean for you. Also, in this special edition of The Green Letter, Picarro provides our top five takeaways and links to other critical documents that should help keep you informed. On the Picarro Community Gas Forum, we have opened several threads to keep the conversation going.

The 11 amendments in short [pp. 31892-31893]:

-

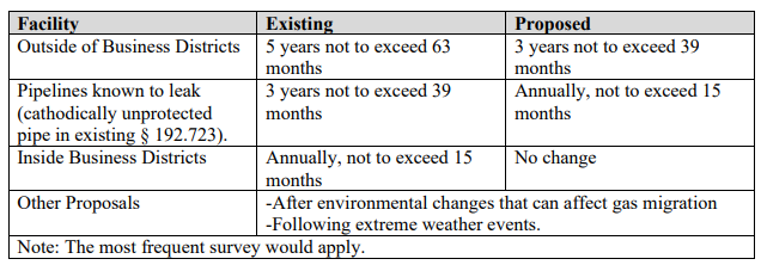

Increase leak survey frequency from 5 years to 3 years and annually depending on the pipe material, operation conditions and maintenance history

-

Introduce an ALDP performance standard with a minimum detection limit of 5 ppm

-

Identify, locate, classify and repair all leaks

-

Repair all leaks in a specified period of time in function of grade and size

-

Reduce intentional emissions such as blowdowns

-

Reduce emissions from relief devices

-

Require written procedures to eliminate hazardous leaks, reduce emissions including through pipeline replacement

-

Report of large methane releases (> 1MMcf)

-

Extend requirements to gathering lines

-

Recognize emissions as a hazard

-

Require quarterly leak surveys on LNG facilities

Starting May 18th, PHMSA opened a 60-day comment period before finalizing the rule. As always, the time schedule and the final results remain uncertain but it is already clear that mobile advanced leak detection systems are part of the solution [p31934, col.2].

Picarro can help gas operators address the intent and the letter of these new requirements in more ways than one. Read on for details.

Accelerated and more complex leak survey schedule:

Challenge: Accelerating leak survey from 5 years to 3 years mechanically increases foot leak survey cost by 65% and the addition of special leak surveys for pipeline segments based on their material, operating conditions, and maintenance history creates complexity for workforce management and multiple compliance reporting including emissions abatement [pp31926, col.3, 31928].

Solution: Picarro’s extensive software stack integrated with GIS and ERP-EAM systems, a simple annual drive provides the foundation for triggering leak investigations following a set of predefined rules including survey frequencies to assure full compliance and support methane abatement and emission report [pp31936, col.3, 31945, col.2, 31954, col.3].

In addition, this annual data set can be used for multiple purposes beyond compliance surveys:

- Support a Super Emitter program that will accelerate the detection and repair of only large leaks for optimal emission reductions [p31941, col.2]

- Optimize surveys on more leak-prone infrastructure beyond material definitions [p31926, col.3]

- Inform pipeline replacement to maximize leak removal and emission abatement [pp31902, col.2, 31938, col.3].

The Advanced Leak Detection Program (ALDP):

Challenge: After recognizing that leak detection and repair practices were insufficient [p31919-col.3], PHMSA proposes an Advanced Leak Detection Program (ALDP) in response to PIPES Act of 2020 [p31932, col.3]. The main changes include the definition of a detection limit of 5 ppm for methane detectors [p31933, col.3], the requirement for written procedures for leak detection [p31935, cl.2], and a stronger definition of grades based on recommendations of the GPTC guide [p31937, col.2].

The NPRM acknowledges that operators can use mobile detection systems followed by investigations [p31934, col.2] as currently performed by several operators using Picarro’s technology with procedures to assure detection capabilities as good or better than requirements.

Solution: The rich and unbiased data set captured by the Picarro system provides the perfect foundation for performance assessment and continuous improvement as called for by PHMSA [p31936, col.1]. It can also be used by operators to dynamically adapt their ALDP to changes in the condition and in the performance requirements of their network.

PHMSA recognizes that a detection limit based on concentration is not representative of leak size and acknowledges proposals for a flow rate-based minimum threshold [p31936, col.3]. Picarro’s AMLD system that can quantify each detection is ready for this evolution towards leak size-driven detection performance.

Accelerated leak repair based on size and grade:

Challenge: One of the main requirements of the NRPM is to repair all leaks with timelines based on grading criteria extracted from the GPTC guide [p31937, col.2].

| Leak grade | Maximum delay to repair |

| 1 | Immediate |

| 2 | 6 months |

| 3 | 2 years |

PHMSA also added a leak size criterion in the definition of grade 2 leaks recognizing the dominant contribution of larger leaks in emissions [p31941, col.2]. Prioritization of repair based on leak size is a key element of an effective methane abatement program but accelerating their detection is equally important since it reduces the time such leaks stay unknown.

Solution: The Picarro Super Emitter program is a direct response to PHMSA’s requirement and beyond it, through accelerated detection, offers the most cost-effective way to reduce methane emissions of a distribution network.

On the other hand, the studies referred to by PHMSA also demonstrated that sources of less than a few tenth of a scfh do not meaningfully contribute to methane emissions. Such a threshold can be used as the minimum definition of a leak [p31938, col.1]. The Picarro system that associates a flow rate to every detection provides the foundation for addressing PHMSA’s requirement to address all meaningful leaks based on size as well as safety.

There is more to be found in this lengthy document, and we encourage everyone to take part in this stage of the process and contribute your comments.

Key quotes of NPRM “Pipeline Safety: Gas Pipeline Leak Detection and Repair”:

These shortcomings in PHMSA’s regulatory regime allow operators to rely on inadequate or ineffective leak detection equipment and practices, rather than encouraging use of commercially available, advanced leak detection technologies and practices appropriate to different gases transported by gas pipeline facility subject to part 192. [p31913, col.1]

AGA et al. observed that studies across the gas industry supply chain show that a majority of emissions come from a small number of high-emitting leaks, and thus leak data analysis enables operators to make substantial inroads on reducing methane emission by identifying and prioritizing repair of the highest emitting leaks [p31913, col.3]

While aircraft can access facilities that may be difficult to access with ground-based vehicles, the speed and altitude required for operation of fixed wing aircraft and helicopters can reduce the reliability of detecting smaller releases [p31915, col.2]

Pipeline operator leak detection and repair practices are similarly insufficient to meet the risks to the environment and public safety from leaks of methane and other gases from gas pipeline infrastructure. Operators employ a spectrum of approaches and technology in connection with leak detection and repair—most of which are focused on compliance with pertinent Federal and State regulations that themselves inadequately address the public safety and environmental risks arising from all leaks on gas transmission, distribution, and part 192-regulated gathering pipelines. [p31919, col.3]

Additionally, operators would have flexibility (as appropriate for their needs and their pipelines’ operational characteristics and environment) in choosing between commercially available, advanced leakage detection equipment satisfying the performance standards proposed in this NPRM for use in those leakage surveys. [p31930, col.3]

Within that common framework, moreover, operators would retain significant flexibility to select (as appropriate for a pipeline’s operational needs and operating environment) a suite of mutually reinforcing leak detection equipment, analytics, and practices, satisfying a baseline leak detection performance standard derived from commercially available advanced leak detection technology in a way that minimizes their compliance costs. [p31933, col.2]

For example, an operator may determine that an efficient means of meeting the ALDP performance standard at § 192.763(b) would be to perform leakage surveys by first using very sensitive (in the sub-ppm or low ppb range) vehicle or aircraft-mounted sensors, followed thereafter by spot-checks using handheld devices with the minimum sensitivity of 5 ppm proposed at § 192.763(a)(1)(ii). Similarly, an operator may supplement any leak detection equipment meeting the minimum sensitivity requirements proposed at § 192.763(a)(1)(ii) with other techniques for pinpointing leak location (e.g., soap bubble testing) or technologies (e.g., devices for measuring release rate for differentiating between leak grades) for grading identified leaks pursuant to PHMSA’s proposed § 192.760. [p31934, col.2]

Specifically, PHMSA proposes to require that an ALDP must be capable of detecting all leaks that produce a reading of 5 ppm or greater of gas when measured from a distance of 5 feet from the pipeline, or within a wall-to-wall paved area. [p31936, col.2]

But mobile leak detection systems and aerial systems that use gas samplers or other sensors to detect leaks at a greater distance may allow for more efficient leakage surveying, but could require more sensitive (sensors in the ppb range) leak detection equipment coupled with advanced analytics

(followed by the use of handheld leak detection equipment to pinpoint leak location) to detect and locate the same leak. [p31936, col.3]

To the extent that operators find that leak rate measurements are helpful for identifying or grading leaks or in calculating estimated emissions consistent with changes to part 191 reporting requirements discussed elsewhere in this NPRM, operators may incorporate leak flow rate metrics within their ALDPs to supplement leak concentration metrics used in PHMSA’s proposed leak detection and ALDP performance standard. [p31936, col.3]

While any leak of methane from a gas pipeline system necessarily entails environmental harm proportional to the amount of methane released to the atmosphere, PHMSA proposes introducing minimum sensitivity standards for leak detection equipment at § 192.763(discussed below) in recognition that some leaks are so small that the harm they present does not warrant expending the resources necessary to detect and repair them, particularly where the leak is approaching the limits of detection with commercially available advanced technologies. [p31938, col.1]

PHMSA also proposes changes to the gas distribution, transmission, offshore gathering, and regulated onshore gas gathering annual reports required by §§ 191.11 and 191.17, consistent with other proposed changes regarding leak grading and repair on those facilities and to collect information on estimated total emissions from each of (1) leaks existing on the operator’s system during the calendar year by grade and (2), other emissions by source category. [p31946, col.2]